CALL TODAY FOR BETA SERVICE

24/7 Servicing - Call Ziggy 021 394 55524/7 SERVICE

We are available 24 hours a day, 7 days a week.

No question is too big or small

We endeavour to solve all call out queries over the phone. This is to save you money and because we appreciate time with our family too. If the query is unable to be resolved over the phone we then evaluate the situation with you and decide when this issue needs to be addressed. Our “Call Out” numbers are very low. We think this is because we believe that “prevention servicing saves you money”.

Call Out Service - Our call out fee is $200 + time, travel & parts between 6pm and 6am Monday to Saturday and all day/night Sundays and Public Holidays.

- We have a 24/7 Tech trouble shooting team at our service for any DeLaval clients

FABRICATION

We have previously fabricated –

- Replacement wash tub lids

- Custom pump covers

- Custom mounting brackets for retro fits

- Retention Arm installs

- Cup Removers

- Cluster upgrades

- New CIP systems

MILKING INSTALLATION AND SERVICE

STORAGE AND COOLING

As DeLaval Service providers we have access to the latest technology in milk storage and cooling.

WATER INSTALLATION AND SERVICE

WATER TANKS

We are suppliers of DEVAN TANKS. We believe Devan Tanks deliver a guaranteed quality product at a competitive price. Devan Tanks is a New Zealand Company with over 20 year’s experience.

Devan Tanks are developed, designed and produced to the highest standards for New Zealand conditions.

PUMPS

We are suppliers of Lowara Pumps as we believe they are a quality product backed by a 100% Kiwi owned and operated business. Please contact us for help selecting the right pump for the job.

Founded in 1968 and based in Montecchio, Vincenza in Italy, Lowara has been serving customers and users of centrifugal pumps for almost 40 years. Lowara is a recognized world leader in stainless steel pump manufacturing technology ranging through turbine, centrifugal and submersible pumps.

Lowara pumps are manufactured in AISI 304 and 316 fabricated stainless steel using laser technology for a diverse range of markets, including commercial, building service, industrial, agricultural, and domestic.

The range of pumps includes vertical multi stage, in-line, end suction close coupled, peripheral turbine, small horizontal multi stage, jet, submersible bore hole, drainage and de-watering pumps, as well as booster and domestic pressure systems.

FILTERS

Water coming from a number of different sources maybe of unsuitable quality for intended use for irrigation, stock, household or other farm activities.

It is important to identify and correct water quality problems that may affect on farm use and productivity.

Puretec’s water filtration solutions ensure the best quality water throughout your property.

MAINTENANCE

SERVICE CONTRACTS

We tailor “Service Contracts” to suit your Milking Plant needs. Having a “Service Contract” in place ensures that your dairy plant receives its service requirements to operate efficiently, effectively and to prevent costly breakdowns. A “Service Contract” also allows you to plan financially for your years servicing needs.

Machine Test:

Visual assessment of plant including

- Vacuum pump drive system condition and connections

- Milk pump condition including plumbing and non-return valve

- Milkline & airlines – condition of plumbing, adequate slope etc

- Cluster – compatibility of liners and milk tube with hardware, condition of rubber components such as liners & claw tubes

- Airflow based tests to cover

- Capacity of vacuum pump compared with manufacturer’s standard

- Reserve airflow available

- Main airline leaks

- Milkline leaks

- Pulsator airline leaks

- ACR consumption (if applicable)

- Cluster air admission

- Pulsator air consumption

- Vacuum regulator leaks

- Calibration test of vacuum gauge

- Vacuum regulation characteristics – ability of VSD/regulator to respond to changes in vacuum and level of under/overshoot

- Pulsation Test – testing every bail and recording pulsation characteristics

- Ratio (min/max)

- Rate (min/max)

- “D” phase minimum

- “B” phase minimum

- Difference in ratio between sides of the pulsator

Mini Test:

- Pulsation Test – testing every bail and recording pulsation characteristics

- Ratio (min/max)

- Rate (min/max)

- “D” phase minimum

- “B” phase minimum

- Difference in ratio between sides of the pulsator

- Airflow based tests to cover

- Capacity of vacuum pump compared with manufacturers standard

- Reserve airflow available

Plant Maintenance Check :

This is a visual assessment of plant which takes approximately 4hrs and covers the following areas:

- Vacuum Pump & drive system

- Milk Pump, pipeline and filter

- Milk Filter

- Pulsation

- Gauge

- Clusters

- Rubberware

- Compressors

- Milkline & Airlines

- Vacuum Regulation

- Auto drains

- CIP Wash System

- Receiver/ Sanitary Trap

- Drop Down System

- Bail Restraint System

- Automatic Cluster Removal System

- Drafting Gates

- Teat Sprayers

- Rotary Centre Gland/s

Blower Vacuum Pump Service:

- Drain oil and refill with new oil to adequate level

- Inspect Coupler

- Test run

Expected Parts used

- Blower gearbox oil

- Coupler (if required)

Compressor Service:

- Drain moisture from pressure tank

- Drain oil and replace with new oil to adequate level

- Replace air inlet filter

- Test run

Expected parts used

- Compressor oil

- Air filter

Milk Pump Service:

- Inspect pump mechanical seal for wear and replace if necessary

- Inspect impellor shaft and back plate for wear

Expected parts used

- Milk pump seal

- Housing O-Ring

Labour and Travel is charged in addition to these services

DRAFTING SERVICES

Save precious time by using an automated system for the segregation of cows and cattle. With many different systems in the product range DeLaval can offer you a solution to suit your needs.

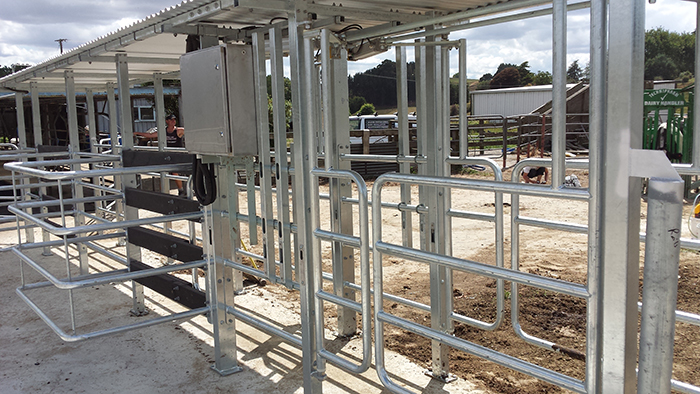

PRANGLEY DRAFTING SYSTEM

One of Ziggy’s recent projects has been installing the latest in Draft-ing Systems into Brian Prangley of Tirau’s shed. The Milfos style gates with Westfalia Surge ID componentry (Dairyplan) makes for a very reliable unit. The unit bolts to the concrete so can there for be added to an existing yard. It can also operate as a stand alone manual unit with the ability to add the componentry at a later date. Complete with pneumatic rams, full roof for shade as well as the steel and wood for the drafting unit all included as a handy kit.